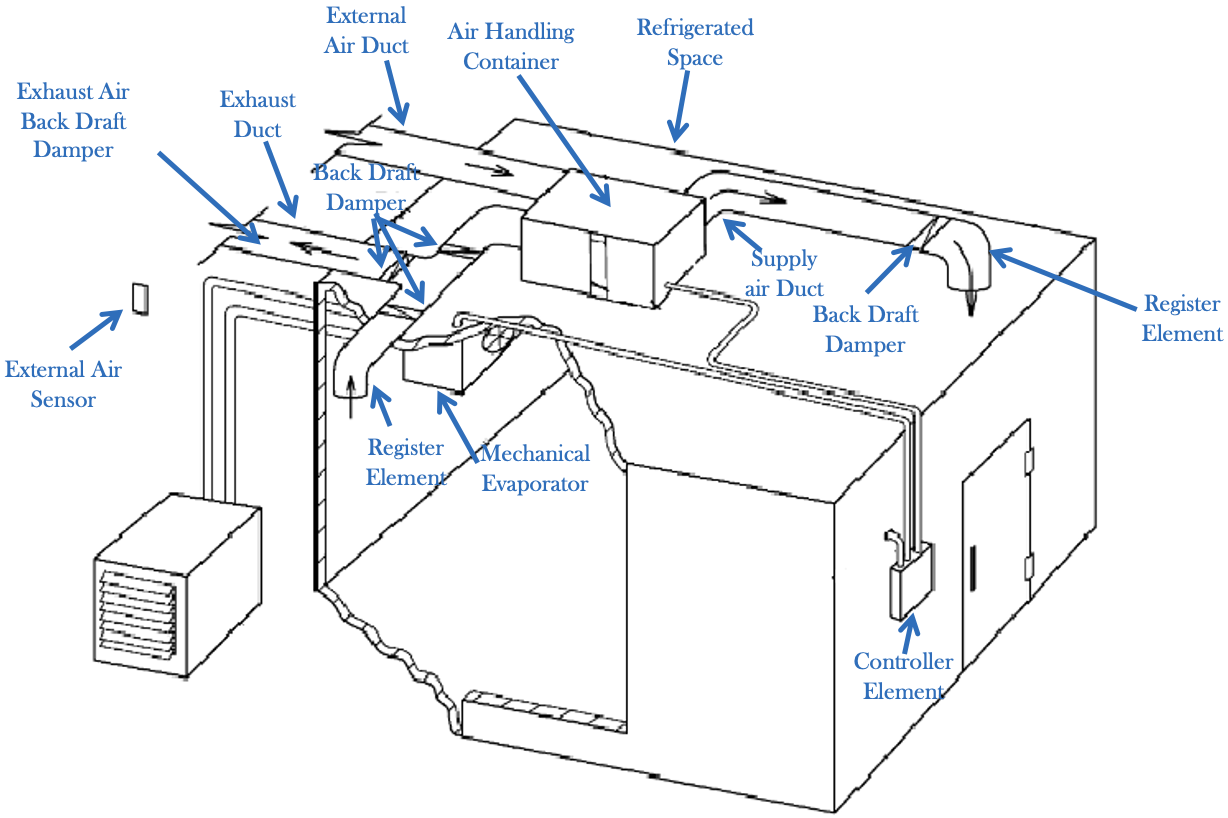

"Ambient Refrigeration System"

IP Approach is pleased to present the exclusive patent for sale “Ambient Refrigeration System” which includes U.S. Granted Patent US 10,240,849 B2 and its Foreign Counterparts CA 2940438 C and WO 2014164892 A1 assigned to Nordic Refrigeration , Inc.

The IP relates to the field of refrigeration. In particular, the inventive technology is directed to improved methods and apparatus for the refrigeration of an enclosed space using external ambient air as a cooling medium.

The IP relates to the field of refrigeration. In particular, the inventive technology is directed to improved methods and apparatus for the refrigeration of an enclosed space using external ambient air as a cooling medium.

The technology disclosed provides the following advantages:

- The invention provides 20-30% annual power saving in comparison to a normal refrigeration system.

- The invention provides the opportunity for high-level air filtration in food storage space.

- It provides tighter temperature and pressure maintenance which is important for food storage.

- The invention provides the ability to use an air handling container that can accommodate various heat load requirements of different sized enclosures such as a ½-25 ton enclosures or more.

- The air recirculation and/or air replacement features with certain filter features help decrease any airborne pollutants that may be present or possible in the refrigerated space.

The global industrial refrigeration market is projected to grow from USD 19.30 billion in 2020 and is expected to reach USD 29.40 billion in 2028, growing at a compounded annual growth rate (CAGR) of 5.4% during the forecast period.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

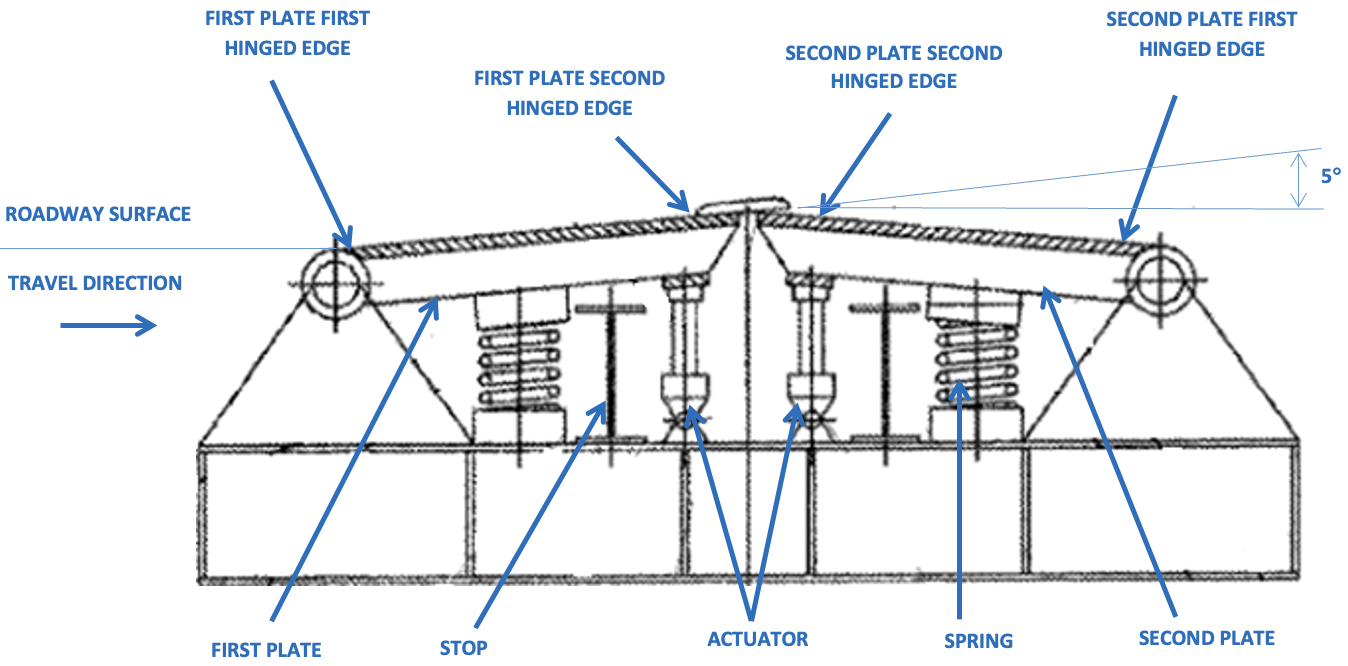

“Hydraulic Energy Collection System”

IP Approach is pleased to present the exclusive patents for sale “Hydraulic Energy Collection System” which includes U.S. Granted Patents US 10,836,245 B1 and US 11,155,152 B2 assigned to Adkins Energy Concepts LLC. The IP generally relates to a system that is embedded in a roadway such that a vehicle traveling over the system compresses a hydraulic fluid, which is used to perform work.

The technology disclosed in the patent portfolio provides the following advantages:

- The invention system is used to drive a hydraulic motor, which can be used to generated electrical power using an electric generator.

- The invention system uses check valves to maintain flow of the hydraulic fluid in a single direction and avoid back-flows.

- The invention system uses a stop to prevent the force from the vehicle from damaging the springs and the actuators.

Global market of Hydraulics is to grow from USD 41.2 Billion in 2022 and is expected to reach USD 49.65 Billion in 2027, growing at a compounded annual growth rate (CAGR) of 3.8% during the forecast period.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

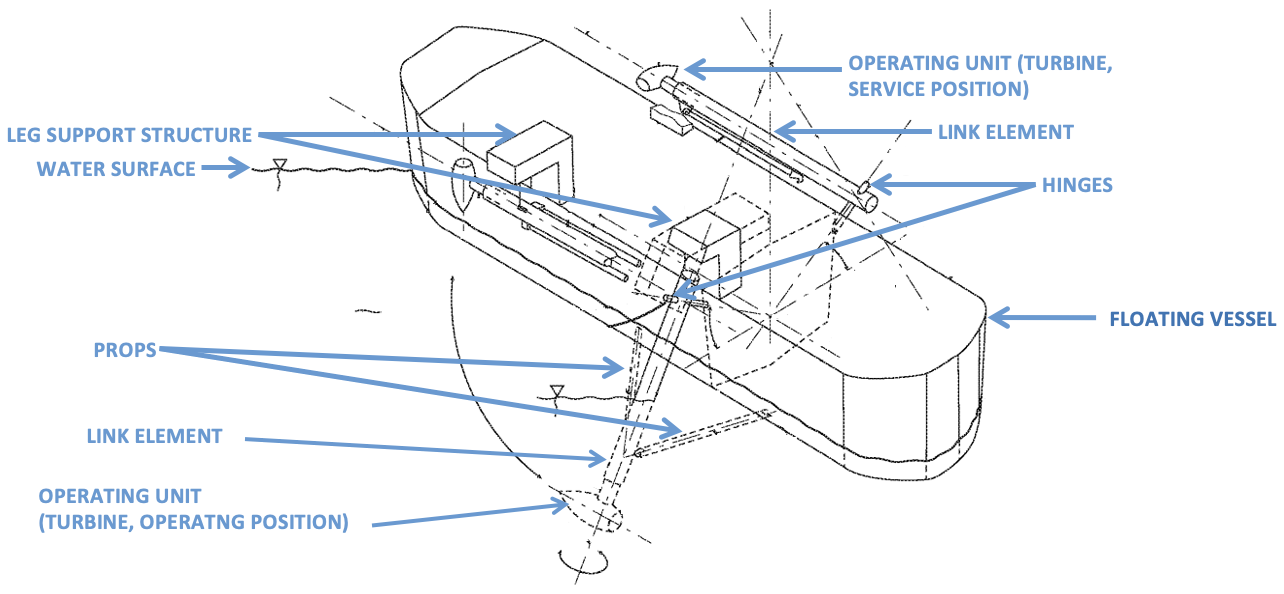

"A Marine Power Plant Assembly"

IP Approach is pleased to present the exclusive patent application for sale “A marine power plant assembly” which includes UK Patent Application GB 2598466 A assigned to Andras Vermes-Gabos. The IP relates to a apparatus and method, for moving a marine plant in and out of the water by means of it being attached to one end of link member in a manner allowing rotation around the longitudinal axis while the link member is enabled to pivot around an inclined axis at its other end.

The technology disclosed provides the following main advantages:

The technology disclosed provides the following main advantages:

- By adopting an inclined hinge around which a link element pivots the system allows movement of the operating unit (underwater plant/nacelle) from the underwater position to a service position close to the main vessel and out of the water. Maneuvering, towing is easier, inspection and maintenance of the operating unit can be carried out from a work platform above water.

- It accomplishes the above by providing an improved hinge assembly whose layout and construction of the hinge is in two parts both aligned on the same axis.

- The hinge allows the mechanical transmission of rotational force (torque) between the operating unit and the main vessel, thus making possible locating the generator(s) - in case of tidal power plants - on the main vessel.

- It provides an improved assembly that utilizes props to stabilize the link element and operating plant in the operating position.

- The system includes a movable/extendable access deck installed in a manner to avoid the path of the link element and operational unit serving as protection to nacelles while towing or berthing takes place and as a work platform for inspection and maintenance.

The Floating power plant market is estimated to grow from USD 9.3 billion in 2021 to USD 27.37 billion by 2031, at a Compound Annual Growth Rate (CAGR) of 11.4% during the forecast period.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

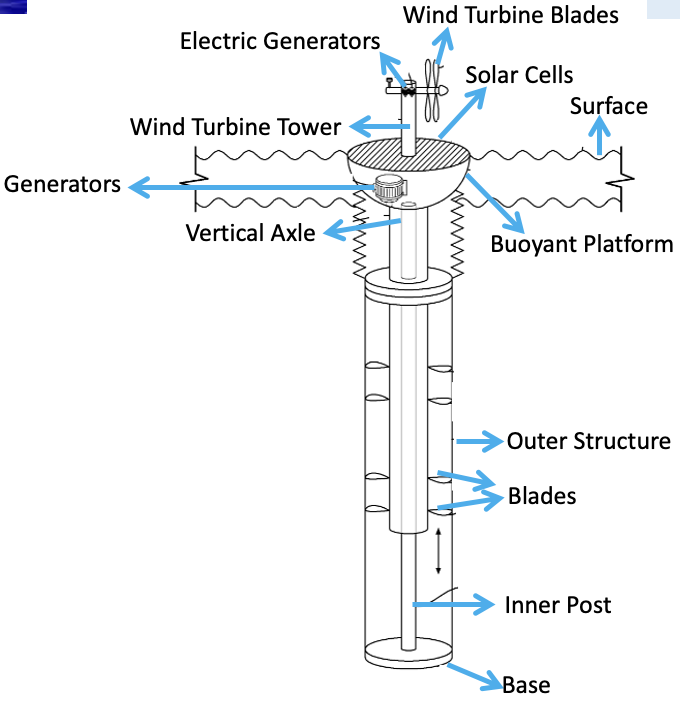

"Generation of Electric Power Using Wave Motion, Wind Energy and Solar Energy"

IPApproach, LLC, is pleased to present the exclusive patent for sale “GENERATION OF ELECTRIC POWER USING WAVE MOTION, WIND ENERGY AND SOLAR ENERGY” which includes U.S. Patent US 10,526,056 B1 assigned to Physician Electronic Networks LLC. The IP relates to the field of power generation and more particularly to a system for generating electrical energy from three sources: using motion derived from waves, wind, and the sun.

The technology disclosed provides the following advantages:

- An electricity generating system is proposed that combines a wind turbine, three dimensional solar photovoltaic cells and pistons moving vertically with ocean waves.

- An enhanced system that includes capturing and conversion of wind energy while also capturing solar energy and/or wave energy, thereby utilizing the same platform with minimal additional expenses, thereby improving cash flow and reducing the time-to-breakeven.

- The solar cells on the wind turbine blades are arranged in a three-dimensional hemi-cylindrical configuration to maximize exposure to the sun by increasing the surface area of photo electric cells and house heating pressurized chambers within the hemi-cylinders.

- The windmill blades are angled between 0 and 360 degrees in relation to the vertical axis to maximize alignment with wind direction.

- The combined harvesting of wind, solar and ocean energy in one structure provides efficient and clean energy at a lower cost compared to conventional wind turbines, solar panels and ocean waves energy systems.

- Lateral Area of a hemicylinder (not including base or ends) is greater than a flat surface of the same base dimensions by a factor of Pi/2.

- The smaller radius of hemicylinders will result in small increase in thickness compared to a flat panel.

- Multiple parallel hemicylinders running the length of each panel.

- The pressurized inner chamber to utilize heat and pressure to make extra electricity is claimed, but not specifically running pipes of liquid or water which is obvious in the art.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

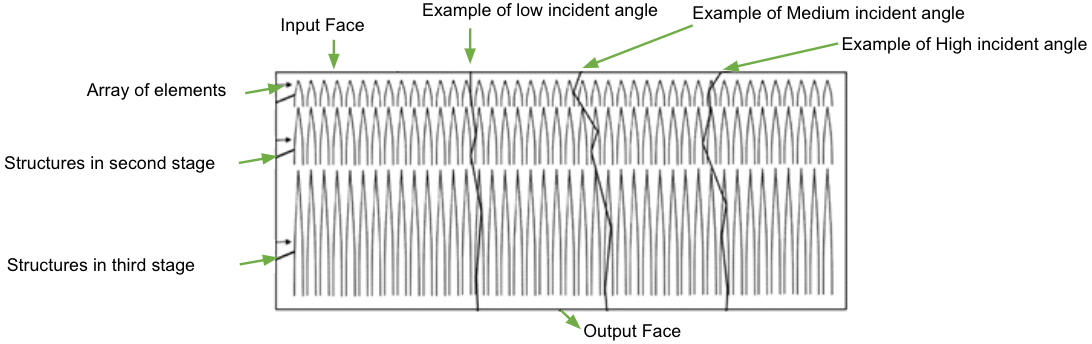

“Light Ray Concentrator"

IPApproach LLC is pleased to present the attached exclusive patents for sale “Light ray concentrator” which include U.S. Granted Patent US10788180 B2 and its Foreign counterparts CA3027431 A1, CN109891149 A, EP3472511 A1, MX2018015505 A and WO2017218716 A1 assigned to Paul E. TANG. The IP relates to a device and system for concentrating light by reducing the angle of light rays arriving at a wide range of incident angles to be output at a narrower range of incident angles of a transmissive optical devices.

The technology disclosed provides the following advantages:

- Indoor natural light illumination: fully functional even on cloudy days.

- more compact, efficient, & flexible transmission of light to building's interior as compared to reflective tubes.

- zero maintenance, Low cost, Low profile and Relaxed geometric constraints.

- Indoor agriculture: With the help of present invention, the light can be piped anywhere, the space can be,

- arranged vertically, hence take up less space.

- low productivity land can be used for farming.

- carbon footprint reduction, water usage reduction, lower pesticide usage and higher yield.

- indoor farming can be done in conventionally constructed space.

- Spot lighting : The collimator will be able to use arbitrary light sources.

- geometric constraints are greatly relaxed by using the collimator.

- Power Generation: Present invention collimator eliminates the need for tracking, and the system is fully functional even under diffused light (i.e. clouds).

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

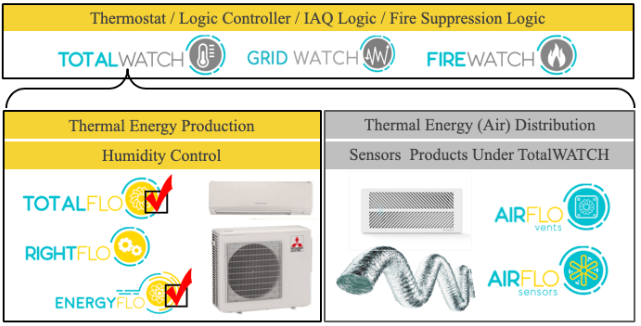

“HVAC SYSTEM”

IP Approach LLC is pleased to present the exclusive patents for sale “Self-modulating HVAC system” which includes U.S. Granted Patent US10408486B2, Published Patent Applications WO2019157111A1, US20200056804A1, US20190346417A1, US20190346170A1 and Unpublished Applications PCT/US19/32201, PCT/US19/32304, 16/183473, 16/282184 assigned to Scientific Environmental Design Inc. The IP relates to a method, a self-modulating HVAC system for improved energy efficiency and performance.

The technology disclosed provides the following advantages:

- HVAC system can achieve more Sensible BTU output with less power consumed for the same given amount of airflow across the indoor coil at 400 CFM/Ton.

- HVAC System increases the SEER rating of the unit.

- Present Invention doesn’t cause various structural issues, such as peeling paint, soggy drywall, frame and trim rot from condensation on windows, and mold or mildew growth in carpets.

- HVAC system is capable of cooling and dehumidifying the air in a home, while maintaining sufficient airflow and energy-efficiency.

- Self-modulating HVAC system have a cooling coil bypass to maintain an appropriate calculated airflow through the conditioned space while limiting the air that passes over the cooling coil to achieve an optimal sensible BTU rate for energy efficiency without adversely affecting the latent moisture removal side of air conditioning.

The global HVAC systems market size was valued at USD 130.5 billion in 2019 and is projected to register a CAGR of 6.1% from 2020 to 2027. The global net zero energy buildings (NZEB) market stood at $896.6 million in 2018, and it is expected to reach $2,106.6 million by 2024, demonstrating a CAGR of 15.6% during the forecast period.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

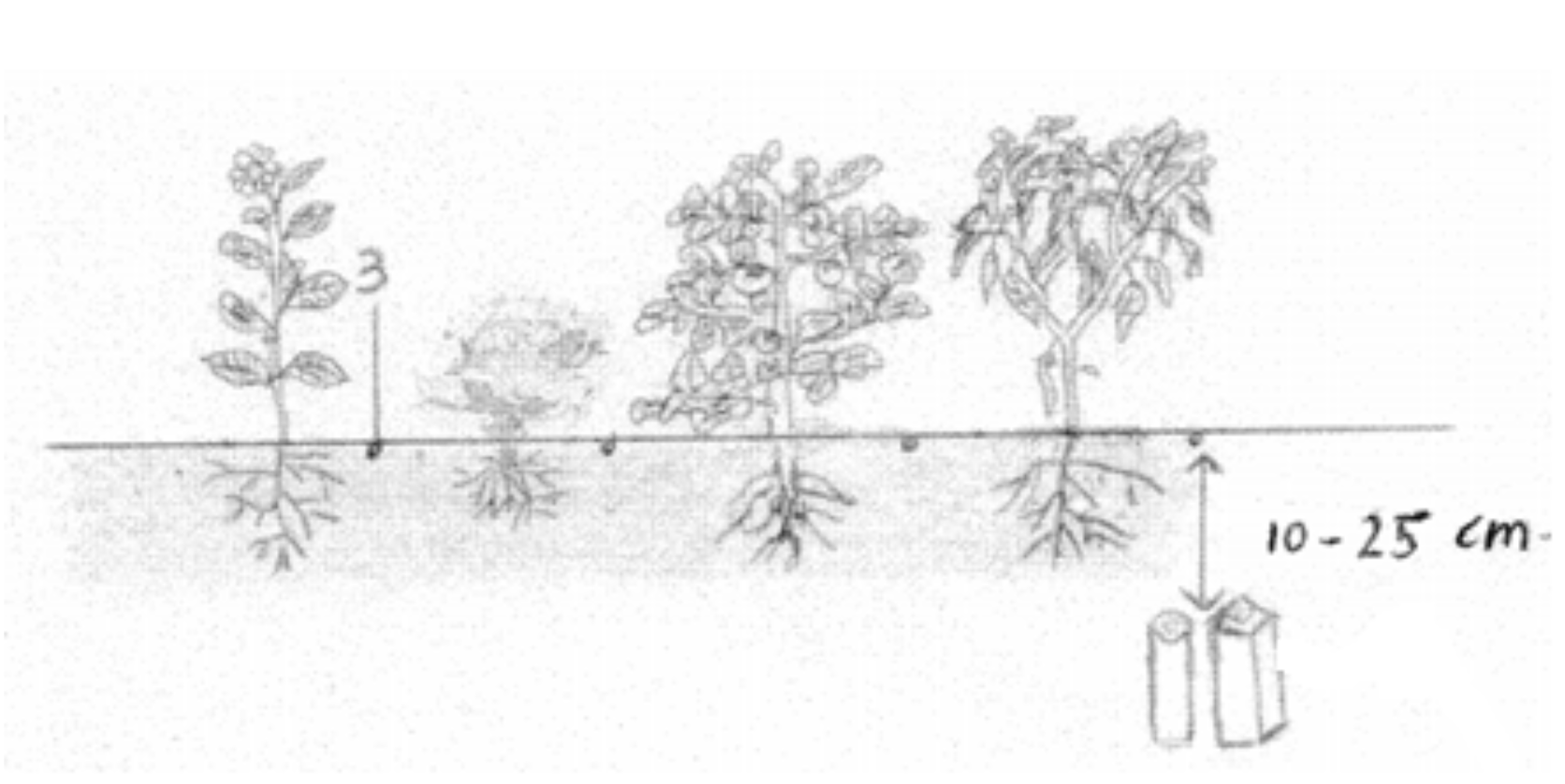

“UTILIZATION OF IRRIGATION WATER SAVER”

IPApproach LLC is pleased to present the exclusive patent for sale “IRRIGATION WATER SAVER” which includes U.S. Patent US 10334795 B2, GCC patents GC 0004596, GC 0008852, Australian application AU 2017258934 A1 and Egyptian application 1866/2017 assigned to Mubarak Abdulla Mubarak Albuainain. The IP relates to a method of reducing the amount of water used in irrigation of a tree/plant.

The technology disclosed provides the following advantages,

- The device has ability to absorb and store irrigation water in high capacity up to 300% in higher quantity than soil ground.

- The device is the sustainable source of water which supplies the roots of a tree or plant in areas which suffer from shortfall of rain, with poor type of soil and depletion of underground water reservoir.

- The device absorbs more water and make the surrounding soil constantly moisture and wet by allowing diffusion of water from device.

- The device will help reduce the amount of irrigation water consumption between 20% to 30%.

- The device have greater water absorbing ability than the sandy soil thereby limiting the loss of water into the ground and maintaining a degree of moisture to the surrounding area under in proximity to said tree/plant especially in poor sandy soil.

The device will be inserted under large trees vertically within the range of depth of 50cm to 100cm; medium trees (i.e. cotton; corn, pomegranate, banana, appte, orange, grape...etc) within the range of depth of 25cm to 50cm; plants (i.e. lettuce, cabbage, tobacco, beans, peas, egg plant, chili, tomato ...etc.) within the range of 10cm to 25cm. The size/length is according to the size and age of tree/plant. Large trees, the size /length of the device is within the range of 25cm or longer, medium trees within the range of 15cm to 25cm and plants within the range of 5cm to 10cm. The number of device required is according to size and age of tree/plant and the season. Large tree at rate of 2 devices in winter and a minimum rate of 4 devices in summer; medium trees at rate of 1 device in winter and a minimum rate of 2 devices in summer; plants at a minimum rate of 1 device in season.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

“METHOD OF HEAT TREATING MAGNESIUM ALLOYS & MAGNESIUM GRAIN REFINING USING VANADIUM”

IPApproach LLC, is pleased to present the attached exclusive patents for sale “METHOD OF HEAT TREATING MAGNESIUM ALLOYS” which include U.S. Patent US 8,414,717 B2 and “MAGNESIUM GRAIN REFINING USING VANADIUM” which include U.S. Patent US 8,784,579 B2 assigned to Joka Buha.

The patent US 8,414,717 B2 relates to the method for low temperature heat treatment of an age-hardenable magnesium based alloys. The technology disclosed provides the following advantages,

- Age hardening of magnesium based alloys can be effected at significantly lower temperatures than are typically used during conventional T6 ageing,

- The tensile properties of most heat treatable magnesium alloys are limited compared to those of the currently used aluminum alloys, which is one of the main limitations for the wider application of magnesium alloys but the present invention includes a method to improve the tensile strength of magnesium alloys.

- The enhanced ageing response typically comprises at least an improvement in both tensile strength and ductility.

- The low temperature heat treatment is accelerated, resulting in improved mechanical properties, such as ductility, strength and hardness levels, comparable to or better than those in the T6 condition.

- Fracture toughness of alloys can be also significantly improved through age hardening.

- An increase in the heat treatment temperature and the change of GP zone type, size, morphology and density in general results in increase in tensile strength and hardness while the ductility and fracture toughness remain improved compared to the T6 condition.

The patent US 8,784,579 B2 relates to process of grain refining magnesium metal or magnesium based alloy which includes the step of providing a melt of magnesium alloy wherein melting includes grain refining agent like vanadium. The technology disclosed provides the following advantages,

- The inventive vanadium grain refiner is applicable to all magnesium-based alloys and to both cast and wrought magnesium based alloys, particularly those where magnesium comprises more than 75 wt % (weight percent).

- Presence of a trace amount of grain refiner like vanadium in the magnesium solid solution significantly improves the magnitude and kinetics of hardening during ageing.

- Refining Agent like Vanadium used in this invention has a multiple beneficial effect on some alloys, which is not observed with grain refiners such as zirconium or carbon and carbon-bearing compounds. This makes vanadium a highly suitable and preferred choice as grain refiner even for magnesium alloys that have traditionally been grain refined by zirconium.

- By using a grain refiner comprised of vanadium metal alone or vanadium metal in the combination with one or more alloying elements intended to be present in the magnesium alloy, it is possible to produce uniform grain size of cast alloys which is at least two times smaller than when the said grain refiner is not used, thereby significantly improving the mechanical properties of cast alloys and wrought products, particularly the tensile properties in the as-cast state.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

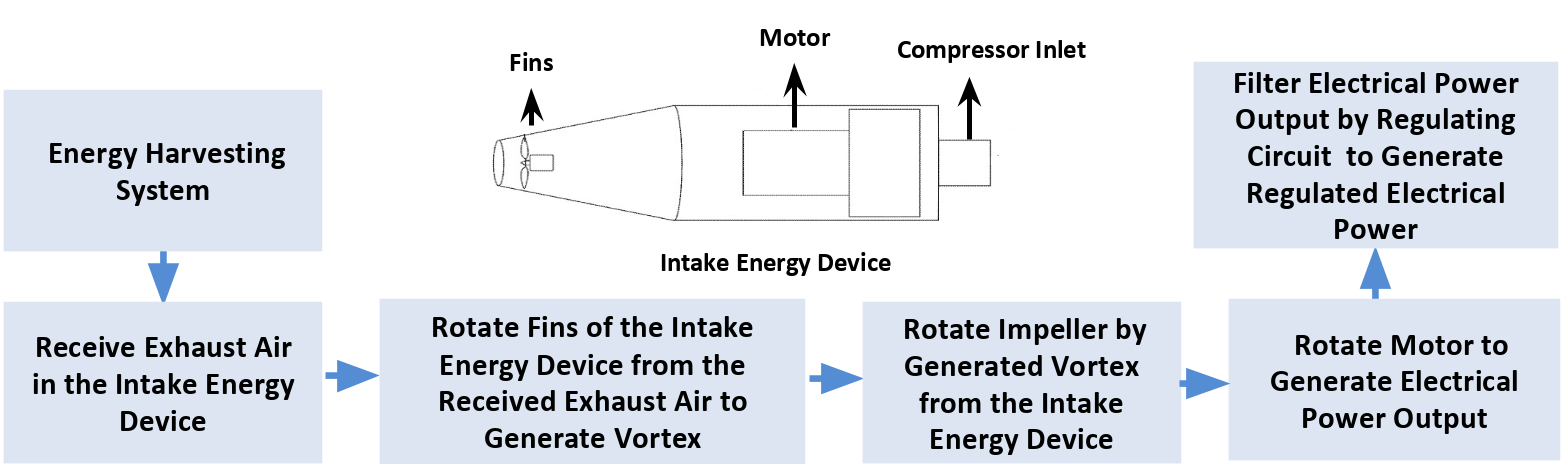

“Energy Harvesting System”

IPApproach LLC is pleased to present the exclusive patents for sale “ENERGY HARVESTING SYSTEM” which include U.S. Patent US 10170960 B2 assigned to GIANFRANCO GUERCIO. The IP relates to Energy Harvesting System for effectively harvesting kinetic energy from exhaust air and converting the kinetic energy to electricity.

The technology disclosed provides the following advantages:

- The system utilizes the energy of exhaust air and converts to produce electrical power.

- The energy harvesting system solves the problem of high electric bills and harnesses the wasted energy making a better efficient operation for the power plant (i.e. maximizes efficiency of existing power generation plants).

- Any type of manufacturing plant can adopt this energy harvesting system (Ease of Implementation)

- The energy harvesting system provides electrical power feed back into an electrical network using any existing system of compressed air or vacuum air for industrial applications.

Energy harvesting system market is estimated to grow from USD 311.2 Million in 2016 to USD 645.8 Million by 2023, at a CAGR of 10.62% during the forecast period. The major factors driving the growth of this market include growing demand for safe, power-efficient, and durable systems that require minimum or no maintenance, extensive implementation of IOT devices in automation and energy harvesting technology in building and home automation, and increasing trend for green energy and favorable initiatives by the governments.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

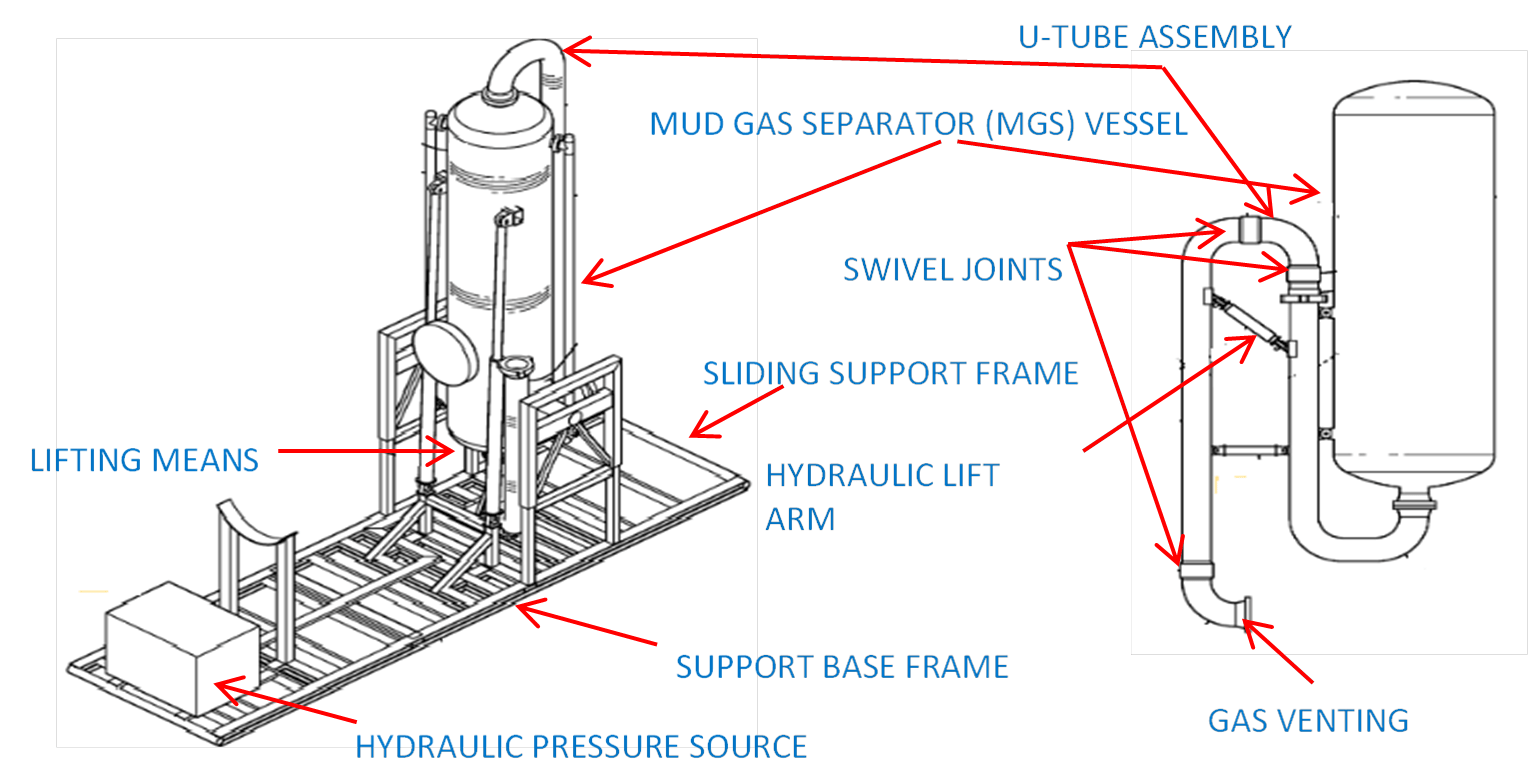

"Mud Gas Separator - Craneless MGS Vessel and Swivel Joint U-Tube Mud Line"

IPApproach, LLC, is pleased to present the exclusive patent for sale “MUD GAS SEPARATOR - CRANELESS MGS VESSEL AND SWIVEL JOINT U-TUBE MUD LINE” which includes the Patent US9962630 and US10094184 assigned to Camaron M. Cox. The IP relates to Mud gas separator (MGS) vessel for connection to a high pressure output from a drilling operation.

The technology disclosed provides the following advantages:

- Provides crane-less elevatable operation of mud gas separator (MGS),

- Provides fast and efficient connection and disconnection of the MGS between the high pressure input lines and the shale shaker and mud pits into which the degassed mud is returned.

The global drilling tools market is expected to grow from 6.73 billion USD in 2017 to 8.61 billion USD by 2022, at a compound annual growth ratio (CAGR) of 4.75%. The market growth for drilling tools is mainly driven by increasing drilling activities as well as the development of unconventional hydrocarbon resources. Another factor driving the demand for drilling tools is the increasing energy demand and growing oil & gas production in oil-importing countries to reduce trade deficits.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

“Compositions and Methods to Reduce Global Warming Caused by Gasoline and Spark Ignited Internal Combustion Engines”

IPApproach LLC is pleased to present the exclusive patent for sale “Compositions and methods to reduce global warming caused by gasoline and spark ignited internal combustion engines” which includes U.S. Granted Patent US 9,540,991 B1 assigned to Marie Talbert. The IP relates to, gasoline composition changes that will lower carbon levels in the atmosphere, and also new methods of fuel use that further reduce carbon levels and global warming.

The technology disclosed provides the following advantages:

-

- The modified gasoline of this invention vaporizes more readily and requires less compression and/or spark advance to vaporize. Hence, saves gasoline and lowers global warming.

- It helps in reduction of global warming caused by gasoline and spark ignited internal combustion engines.

- The modified gasoline of present invention has a lower energy density than current gasoline.

- The invention improves fuel combustion efficiency, lower engine exhaust temperatures and lower exhaust pollutants.

- This system performs equal to or better than current gasoline in current vehicles.

- Modified gasoline of this invention have lower Reid vapor pressure with and no oxygenates, hence it lowers global warming.

- The modified gasoline facilitates reliable ignition at very high air to fuel ratios under ambient conditions.

The global Green Gasoline market is estimated to grow from USD 253.2 Million in 2018 and is expected to reach USD 3142.16 Million by the year 2026, at a Compound Annual Growth Rate (CAGR) of 37% during the forecast period.

Please contact Justin Ehrlickman via email at justin@ipapproach.com or phone at 845-558-7901 to receive a Brokerage Marketing Package.

IPApproach has patents for sale in the following categories:

Advertising

Automotive & Vehicles & Trailers

Biometrics & Touch Screen

Construction

Consumer - Electrical

Consumer - Other

Data Management

Delivery & Routes

Display and Imaging

Energy

Gaming

Internet of Things (IOT)

Medical

Mobile & Telecommunications

Office Furniture / Equipment

Other

Security

Semiconductor and Packaging

Social Media

Software

Tools & Brackets

Trademark

Video

Wireless

Other - TransactionsIP